- English

- Sales & Support:+86 18926075763

| Place of Origin: | Guangdong, China |

| Brand Name: | RDY |

| Certification: | Customer requirement |

| Model Number: | RDY-SUP-4 |

| Minimum Order Quantity: | 5000 Pieces |

|---|

| Price: | 0.02 |

|---|---|

| Packaging Details: | Standard cartons or Can be customized according to your Spec |

| Delivery Time: | 7-15 working days after design |

| Payment Terms: | Customer requirement |

| Supply Ability: | 10000 Piece/Pieces per Day |

Custom zipper bags are more important, do you know how to custom zipper bags, as a professional zipper bags manufacturer we will talk something about custom zipper bags, such as custom zipper bags materials, are custom zipper bags eco friendly. The most commonly used materials for custom zipper bags are plastic, such as LDPE, HDPE, PP, or PVC. These materials are chosen for their durability, strength, and flexibility. They are also lightweight, which makes them ideal for shipping and transportation. Plastic zipper bags are commonly used in the food industry as they offer a barrier against moisture and air, keeping the contents fresh for a longer time. Custom zipper bags can also be made from eco-friendly materials, such as recycled plastics or biodegradable materials. These materials are a great choice for companies looking to reduce their carbon footprint or appeal to environmentally conscious customers. The production process of custom zipper bags involves designing the bag, selecting the material, and printing the design. The bags are then cut, folded, and sealed to create the final product. It is important to ensure that the design is high quality and suits the intended purpose of the bag, such as providing enough space for the product or displaying branding effectively. There are a few things to keep in mind when ordering custom zipper bags. Firstly, it is important to choose a reputable supplier who uses high-quality materials and has experience in producing the bags. Additionally, it is important to select the right size, style, and material for the intended use of the bag. Lastly, it is important to consider the environmental impact of the bag, especially if the bag will be used for food packaging. In summary, custom zipper bags are a versatile and practical solution for packaging and storage. They are made from high-quality materials, come in a wide range of colors and styles, and can be produced with eco-friendly materials. The production process involves designing, selecting materials, and printing the design. It is important to select a reputable supplier and consider the environmental impact of the bags when ordering.

| Aspect | Description |

|---|---|

| Material | The type of material used for the bag, such as polyethylene, polypropylene, PVC, nylon, polyester, cotton, canvas, jute, kraft paper, or laminated paper. |

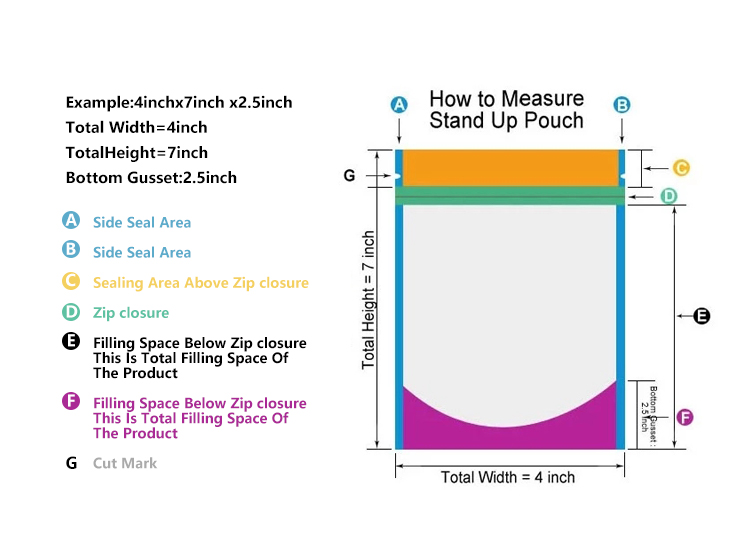

| Size | The dimensions of the zipper bag, including length, width, and height, measured in inches or centimeters. |

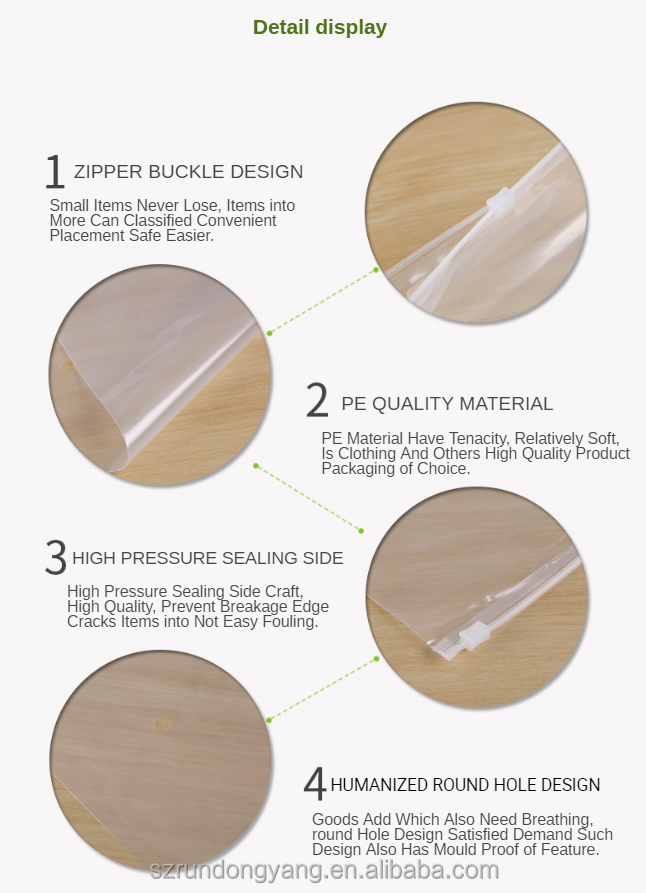

| Zipper Type | The type of zipper used, such as nylon zipper, metal zipper, or plastic zipper. |

| Bag Color | The color or colors of the bag, which can be customized to match your branding or design preferences. |

| Printing Options | The available printing techniques, such as screen printing, digital printing, or heat transfer, to add logos, graphics, or text to the bag. |

| Features | Additional features that can be included, such as a front pocket, handle, grommets, or a clear window. |

| Minimum Order Quantity (MOQ) | The minimum number of bags required for a custom order. Suppliers may have varying MOQs based on their production capabilities. |

| Customization Options | The level of customization offered, including the ability to select material thickness, zipper placement, or special finishes like matte or glossy. |

| Sustainability Options | Whether eco-friendly materials, such as recycled or biodegradable options, are available for environmentally conscious choices. |

| Lead Time | The estimated time required for production, including printing, customization, and delivery. This can vary depending on the supplier and order quantity. |

| Pricing | The cost per unit or pricing structure based on factors such as material, size, complexity of customization, and order quantity. |

| Supplier Information | Contact details and relevant information about the supplier offering custom zipper bags, such as their website, location, and customer reviews. |

Custom zipper bags are bags made from various materials, such as plastic, vinyl, or cloth, that have a zipper closure. The bags are customizable in terms of size, shape, color, design, and branding, making them ideal for packaging, promotions, and advertising. They can be used for storing and transporting a wide range of items, including food, beauty products, toys, stationery, and clothing. Custom zipper bags are convenient, reusable, and environmentally friendly and can be ordered in large or small quantities to suit various needs.

1. Versatility: Custom zipper bags can be used for various purposes, including storage, display, and packaging.

2. Durability: Custom zipper bags are made with high-quality materials that ensure their durability and longevity.

3. Cost-Effective: Custom zipper bags are an affordable alternative to other packaging methods, such as boxes or pouches.

4. Convenience: With a zipper closure, custom zipper bags are easy to open and close, making them convenient for customers.

5. Security: Custom zipper bags provide an extra layer of security for your products, ensuring they stay protected during shipping or storage.

6. Sustainability: Custom zipper bags can be made from eco-friendly materials, such as biodegradable plastics, which helps to reduce your environmental impact.

1. Choose the type of zipper bags you want: Decide on the size, material, and color of the zipper bag you want. You can choose from a variety of materials like vinyl, nylon, and polyester.

2. Design your zipper bags: Decide on the design for your personalized bag. You can add your own logo, image, or message to make it unique.

3. Choose your printing method: Select the printing method you want for your zipper bag. You can choose from screen printing, digital printing, or embroidery.

4. Choose your custom zipper bags colors: Decide on the colors you want for your bag. Most manufacturers allow you to choose from a wide range of colors.

5. Place your custom zipper bags order: Once you have finalized your design, colors, and printing method, place your order with the manufacturer.

6. Receive your custom zipper bags: After your order has been processed, you will receive your custom zipper bags. Make sure to inspect them carefully to ensure they meet your requirements.

7. Enjoy your custom zipper bags: Use your custom zipper bags for your personal or business needs. They make great giveaways, marketing tools, or storage solutions.

| Are custom zipper bags eco friendly?If custom zipper bags are eco friendly, It depends on the materials used to make the custom zipper bags. If the bags are made from eco-friendly materials such as recycled or biodegradable materials, then they can be considered eco-friendly. However, if the custom zipper bags are made from non-biodegradable materials such as plastic, then they are not eco-friendly. It is important to check the materials used before purchasing custom zipper bags to ensure that they are environmentally-friendly. Why we should custom zipper bags1. Enhance brand recognition: Custom zipper bags with your company logo or name can help promote your brand and make it easier for customers to remember your business. 2. Improve product presentation: Custom zipper bags with unique designs or prints can make your products more attractive to customers and potentially increase sales. 3. Increase customer loyalty: Custom zipper bags can be seen as a thoughtful touch and make customers feel valued. 4. Better product protection: Custom zipper bags can be made with specific materials or features to better protect your products from damage during transport or storage. 5. Reduce waste: Custom zipper bags can be designed to be reusable, reducing the amount of waste generated by single-use plastic bags. Custom zipper bags process1. Material selection: The next step is to select the appropriate materials for the zipper bags. The options include plastic, paper, or fabric-based materials depending on the intended use and durability required. 2. Manufacturing: The manufacturing process will depend on the selected materials and design specifications. Typically, the process involves cutting and shaping the material into the desired shape and size, adding features like zippers, and applying any print or labeling. 3. Quality control: Quality control is an essential step throughout the manufacturing process. This ensures that the zipper bags meet the proper specifications and quality standards. 4. Packaging: Once the custom zipper bags are manufactured and quality-checked, they are packaged and prepared for shipping or distribution. 5. Distribution: The final step is to distribute the custom zipper bags to the intended locations, such as warehouses or retail stores, where they will be sold or used. |

The first patent for a zipper was filed in 1851 by Elias Howe, who also invented the sewing machine. However, it was not until 1913 that a successful, commercially viable zipper was created by Swedish-American engineer Gideon Sundback. Sundback's design was called the "Hookless Fastener" and it used interlocking teeth instead of hooks and loops.

In the 1950s, custom zipper bags began to gain popularity as a convenient way to store and transport goods. They were originally made of simple materials like plastic and were only available in a few basic sizes.

As the demand for custom zipper bags increased, manufacturers began to experiment with different types of materials and designs. Today, custom zipper bags are available in a variety of materials like nylon, cotton, polyester, and even eco-friendly options like organic cotton and recycled materials.

Custom zipper bags have become an indispensable part of modern life, used for a variety of purposes including travel, storage, and packaging. With the constant innovation in materials, designs and production techniques, the future looks bright for custom zipper bags.

1. Store in a Cool, Dry Place: It is important to store custom zipper bags in a cool, dry place. Moisture and humidity can cause the material to deteriorate, and that could compromise the zipper. The costom zipper bags should also be kept out of direct sunlight.

2. Handle with Care: Custom zipper bags should be handled gently to avoid damaging the zipper. Avoid pulling too hard on the zipper when opening or closing the bag as this can cause the zipper to break. Take care when handling the custom zipper bags to protect the contents inside as well.

3. Choose the Right Size: Be sure to choose the right size of custom zipper bags to fit the contents. Overstuffing the bag can put undue stress on the zipper, resulting in a broken or damaged zipper.

4. Check the Quality: Always check the quality of the zipper before purchasing or ordering custom zipper bags. A high-quality zipper will be more durable and less likely to break or malfunction.

5. Clean and Maintain Regularly: To extend the life of the custom zipper bags, it is important to clean and maintain them regularly. Clean the custom zipper bags gently with mild soap and water, rinse thoroughly, and let them air dry. This will help to keep the zipper and material in good condition.

How to reduce the cost of custom zipper bags1. Simplify the Design: The complexity of the design and the number of colors used will affect the cost of producing custom zipper bags. To reduce costs, simplify the design and use only a few colors. A simple design with one or two colors is often just as effective as a complex one and can reduce the cost of production. 2. Reduce Packaging: Packaging is an important part of custom zipper bags, but it can also add to the cost. To reduce costs, choose a simple packaging option that still protects the bags during transportation. For example, you can opt for a clear plastic bag or a cardboard box instead of a custom printed box. 3. Choose the Right Material: The material used to make custom zipper bags can affect the overall cost. Choosing a different material, such as a thinner or less expensive plastic, can help you reduce the cost of production. However, it is important to balance cost and quality to ensure that the bags still meet your needs. 4. Work with an Experienced Manufacturer: By working with an experienced manufacturer, you can benefit from their expertise and knowledge of the industry. They can help you choose the right materials, design, and packaging options to reduce the cost of production while still meeting your needs. They can also suggest ways to optimize the manufacturing process to reduce costs. |  |

Custom zipper bags application1. Retail packaging: Custom zipper bags are commonly used in retail stores to package products like snacks, pet food, coffee, and tea. 2. Organizing: The bags can be used to organize and store small items like jewelry, craft supplies, and office supplies. 3. Travel: Custom zipper bags are perfect for storing toiletries, makeup, and other personal items when traveling. 4. Medical applications: These bags are commonly used to store medical supplies like first aid kits, syringes, and medication. 5. Food storage: Custom zipper bags are a great way to store food items like vegetables, fruits, and leftovers. 6. Promotion: Custom zipper bags can be used as promotional items for businesses, events, and campaigns. 7. Protection: They can be used to protect sensitive items like electronics, documents, and artwork. Overall, custom zipper bags are a versatile packaging solution that can be used for almost any application. | |

1. Food packaging – Custom zipper bags are used for packing a variety of food items, such as fruits, vegetables, nuts, and grains. The airtight and resealable features of zipper bags help to maintain freshness and prevent contamination.

2. Medical and pharmaceutical packaging – Custom zipper bags are used for packaging medical equipment, devices, and drugs. The bags are designed to be tamper-evident, secure, and air-tight to minimize contamination and maintain sterility.

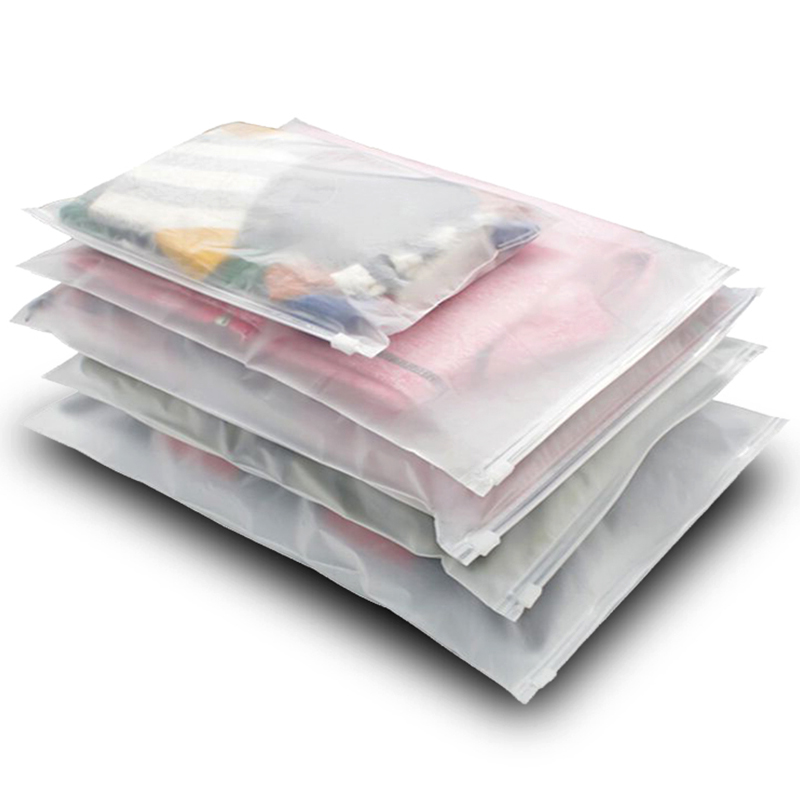

3. Retail packaging – Custom zipper bags are used for packaging consumer goods, such as clothing, toys, and accessories. The bags can be customized to reflect branding and enhance the product's appearance.

4. Home organization – Custom zipper bags are used for organizing and storing household items, such as clothing, bedding, and accessories. The bags can be labeled and stacked for easy organization.

5. Travel and outdoor activities – Custom zipper bags are used for packing and organizing items for travel and outdoor activities. The bags are durable, waterproof, and resealable, making them ideal for storing food, toiletries, and other essentials.

1. Polyethylene: Polyethylene is an affordable and versatile option that is often used for custom zipper bags. It is a common material used in custom plastic zipper bags.

2. Polyester: This is another durable and strong material that is often used for custom zipper bags. It has a sleek, modern appearance and can withstand wear and tear.

3. Vinyl: Vinyl is a popular choice for custom zipper bags because of its water-resistant properties. It is easy to clean and maintain.

4. Cotton: Cotton is a natural material that is breathable and eco-friendly. For custom zipper bags, it is often blended with other materials like polyester for added durability.

5. Canvas: Canvas is a heavy-duty fabric that is very durable and can withstand heavy use. It is often used for custom zipper bags that need to hold heavy items.

6. Leather: Leather is a luxury material that can add a sophisticated touch to custom zipper bags. It is durable and can last for years with proper care.

7. Recycled Materials: Many manufacturers are now using recycled materials like recycled polyester or recycled plastic to make custom zipper bags, making them more eco-friendly.

| Material | Description |

|---|---|

| Polyethylene | Lightweight, durable, and moisture-resistant plastic material. |

| Polypropylene | Sturdy and flexible plastic with excellent heat and chemical resistance. |

| PVC (Polyvinyl Chloride) | Clear, transparent plastic with good durability and resistance to chemicals. |

| Nylon | Strong and abrasion-resistant synthetic fabric with good flexibility. |

| Polyester | Durable, wrinkle-resistant fabric known for its strength and longevity. |

| Cotton | Natural, breathable fabric that is soft, eco-friendly, and easily customizable. |

| Canvas | Heavy-duty, tightly woven fabric that offers durability and stability. |

| Jute | Natural fiber with a coarse texture, often used for eco-friendly and rustic designs. |

| Kraft Paper | Sturdy, eco-friendly paper material with good tear resistance and natural appeal. |

| Laminated Paper | Paper material coated with a layer of plastic for added strength and moisture resistance. |

1. Durability: The chosen material for the custom zipper bags should be durable and strong enough to withstand regular use and provide adequate protection to the content. The zipper should also be durable and sturdy to prevent accidental opening.

2. Accessibility: The custom zipper bags should have an easy-to-use zipper system that allows for quick and easy access to the content inside.

3. Customization options: The custom zipper bags should be easily customizable to allow for branding or personalization.

4. Environmental impact: Consider using eco-friendly materials and packaging solutions to minimize the environmental impact of the custom zipper bags.

5. Cost: Custom zipper bags can be expensive, and the cost should be considered when designing the bag to ensure it is within budget.

6. Compliance: If the contents of the custom zipper bags have specific regulations or compliance requirements, the bag design should be compliant with those requirements.

7. Security: For certain contents, such as sensitive documents or valuable items, the custom zipper bags should have additional security features such as tamper-evident seals or locking mechanisms.

8. Functionality: Consider the specific function or purpose of the custom zipper bags and ensure the design and features meet the intended use.

Address: 1609, Tongfang Information Port, Zhongkai High-Tech Zone, Huizhou, Guangdong, China